How to Choose the Right Axle Configuration for a Flatbed Trailer?

Choosing the right axle configuration for a flatbed trailer is a crucial decision that directly impacts its load capacity, stability, and maneuverability. Flatbed trailers are widely used for transporting a variety of goods, and selecting the appropriate axle configuration is essential to ensure safe and efficient transportation. In this guide, we will explore key factors to consider when choosing the right axle configuration for a flatbed trailer.

1. Understand Load Capacity Requirements:

- Gross Vehicle Weight Rating (GVWR): Determine the maximum weight that the flatbed trailer will be required to carry. This includes the weight of the trailer itself along with the weight of the cargo. The GVWR is a critical factor in selecting the appropriate axle capacity.

- Cargo Distribution: Consider the distribution of weight across the trailer. Axles should be strategically placed to ensure even weight distribution, preventing issues such as overloading on one side.

2. Consider Legal Weight Limits:

- Local Regulations: Be aware of legal weight limits imposed by local transportation authorities. Different regions may have specific regulations regarding axle weights, and compliance is essential to avoid legal issues and ensure road safety.

- Axle Spacing: Some jurisdictions regulate the spacing between axles. Understanding these regulations helps in determining the axle configuration that complies with weight restrictions.

3. Evaluate Trailer Length and Deck Type:

- Length of the Flatbed: Longer flatbed trailers may require additional axles to distribute weight effectively and maintain stability. Consider the overall length of the trailer and the type of cargo it will carry.

- Type of Deck: The type of deck on the flatbed, whether fixed or adjustable, can influence axle placement. Adjustable decks allow for flexibility in accommodating different load sizes and weights.

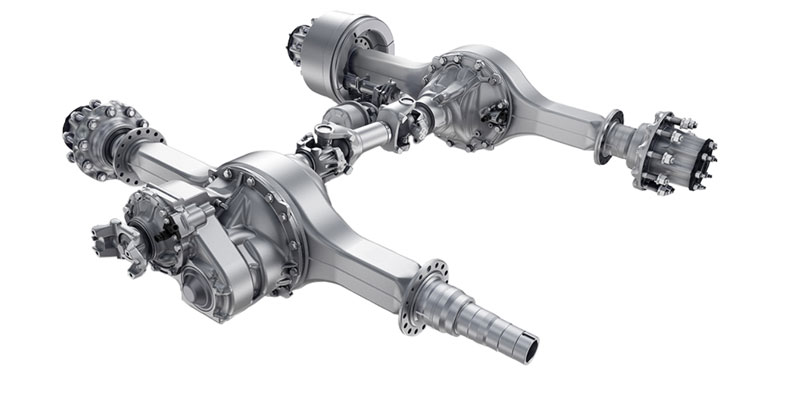

4. Single vs. Tandem Axles:

- Single Axles: Single axles are simpler and more maneuverable, making them suitable for lighter loads and shorter trailers. They are often used in utility trailers and smaller flatbeds.

- Tandem Axles: Tandem axles provide increased load-bearing capacity and stability. They are suitable for larger flatbed trailers and are commonly used for transporting heavier loads over longer distances.

5. Tri-Axle and Multi-Axle Configurations:

- Tri-Axle Trailers: Tri-axle configurations offer even higher load capacity and weight distribution. They are beneficial for carrying heavier loads while maintaining stability and compliance with weight regulations.

- Multi-Axle Configurations: Depending on specific needs, flatbed trailers can have more than three axles, such as quad-axle or even more. These configurations are employed for extremely heavy loads and specialized transport.

6. Consider Suspension Systems:

- Type of Suspension: The type of suspension system used in the axle configuration affects the trailer's ride quality, stability, and load-carrying capability. Common suspension types include leaf spring, air ride, and torsion.

- Adjustable Air Suspension: Some flatbed trailers feature adjustable air suspension, allowing operators to adjust the ride height based on the load. This can be advantageous for optimizing ground clearance and stability.

7. Evaluate Maneuverability and Turning Radius:

- Number of Pivot Points: Consider the number of pivot points created by the axles. Tandem and tri-axle configurations may have more pivot points, impacting maneuverability and the turning radius of the flatbed trailer.

- Steerable Axles: Some configurations include steerable axles to improve maneuverability, especially in tight spaces. This feature can be valuable for navigating urban areas or congested loading docks.

8. Maintenance Considerations:

- Ease of Maintenance: Assess the ease of maintenance for the chosen axle configuration. Consider factors such as accessibility for inspections, lubrication points, and the durability of components.

- Quality of Axle Components: Invest in high-quality axle components to ensure reliability and minimize the risk of breakdowns. Quality components contribute to the overall longevity and performance of the flatbed trailer.

Choosing the right axle configuration for a flatbed trailer requires a thorough assessment of factors such as load capacity, legal regulations, trailer length, and suspension systems. Whether opting for single, tandem, or multi-axle configurations, the goal is to achieve a balance that ensures safety, compliance, and efficient transportation.

For expert guidance on selecting the optimal axle configuration for your flatbed trailer needs, consider reaching out to professionals like Safeeds Transport. Their experience in the transportation industry ensures reliable and secure hauling services.

Get a quote from Safeeds Transport IncBy carefully considering these factors and consulting with industry experts, you can make an informed decision that aligns with the specific requirements of your flatbed trailer, ensuring safe and efficient transport of goods.

Comments

Post a Comment